Several projects in the Machine-building market have been completed by Leerkes Engineering for different clients (in no particular order):

Function Control Research Ltd. Groningen

Function Control specializes in the development and production of high-tech carton board and fine paper mill inspection systems that utilize cutting-edge Vision technology. With a dedicated team of approximately 10 skilled professionals, Function Control is committed to building and delivering their state-of-the-art machines to customers all around the globe.

To learn more about Function Control and their innovative solutions, please visit their website at https://www.functioncontrol.com/

Leerkes Engineering has recently undertaken an important project to enhance Function Control’s operations. Specifically, they have developed and implemented a new Eplan Electric P8 standard and corporate identity for the company. In addition, Leerkes Engineering has also taken the initiative to redesign, improve, and test all of the company’s existing machines to meet the latest standards, such as NEN-EN-IEC 60204, NEN-EN-IEC 61439-1, and NFPA 79. Despite the challenges posed by remote work, Leerkes Engineering has maintained regular communication with Function Control’s employees throughout the project.

TELE Besturingstechniek Ltd. Hengelo

TELE Besturingstechniek is a leading machine builder that operates at the highest level of quality. They tackle even the most challenging projects with ease. With a team of around 25 highly skilled professionals, TELE Besturingstechniek specializes in designing and manufacturing cutting-edge switch and control cabinets for machine builders. Their expertise lies in serving the European and American markets, and they are authorized to certify switch and control cabinets according to UL 508A/CSA.

To learn more about TELE Besturingstechniek and their services, please visit their website at https://telebesturingstechniek.nl/

Leerkes Engineering has successfully completed several projects for TELE Besturingstechniek, utilizing their expertise in producing electrical schematics with both Eplan Electric P8 and Eplan Pro Panel. Despite the remote nature of the work, Leerkes Engineering has maintained frequent communication with the employees of TELE Besturingstechniek throughout the project, ensuring a collaborative and seamless process.

Cleanroom Cranes Ltd. Eindhoven

Cleanroom Cranes, a subsidiary of Mennens. located in Eindhoven, specializes in manufacturing lifting equipment for various industries, with a particular focus on cleanroom applications. Their high-quality products are distributed worldwide.

For more information about Cleanroom Cranes and their advanced lifting equipment, please visit their website at https://www.cleanroom-cranes.nl/

Recently, Cleanroom Cranes enlisted the services of Leerkes Engineering to test a project against the rigorous American NFPA 79 standard. In order to sell their machines in the United States, they must meet these stringent safety requirements.

Leerkes Engineering has successfully verified multiple cleanroom portal cranes against the NFPA 79 standard and produced an English-language report outlining its findings and recommendations for the portal crane. Additionally, they have designed an on-location FAT (Factory Acceptance Testing) checklist for NFPA 79, ensuring the highest level of safety and compliance for Cleanroom Cranes’ products.

PIA Service Ltd. Joure

PIA Service, short for Processing & Industrial Automation Service, began as a sole proprietorship in 2007 and has grown into a thriving company with 45 employees. They operate both domestically and internationally, with a strong emphasis on cultivating open and transparent relationships with their clients. This approach enables PIA Service to provide customized automation solutions and tailored advice that aligns with the unique needs of each customer.

For more information about PIA Service and their innovative automation services, please visit their website at https://piaservice.nl/

Leerkes Engineering provided invaluable support to PIA Service by reviewing a project under the stringent UL508A standard, ensuring that the project met the necessary safety regulations. In addition, Leerkes Engineering performed safety calculations using the sophisticated Sistema safety software, compliant with ISO 13849-1, and delivered an extensive report to PIA Service, further enhancing their commitment to safety and quality in their automation projects.

Vanderlande Industries Ltd. Veghel

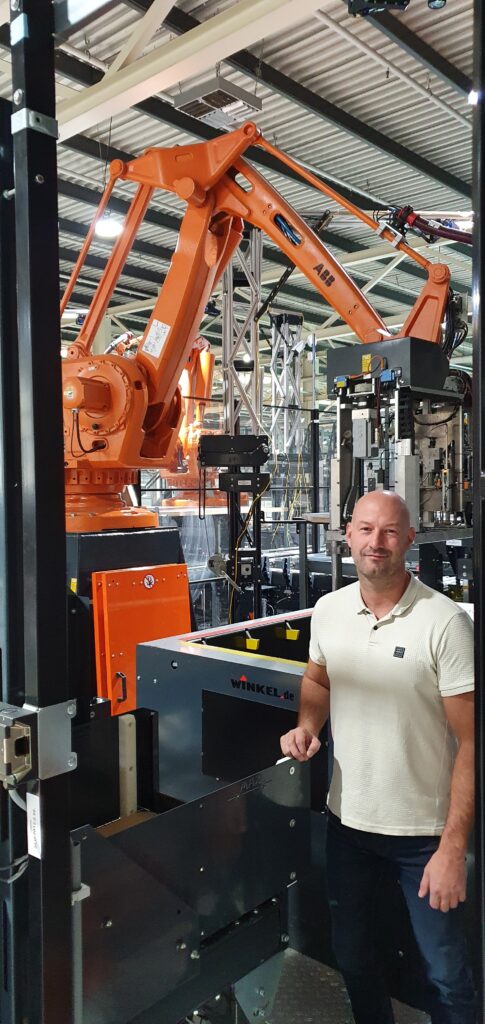

Vanderlande, a subsidiary of Toyota Industries, is located in Veghel and is the global market leader for cutting-edge logistics process automation at airports and in the parcel market. Additionally, the company is a top supplier of process automation solutions for warehouses. By prioritizing the optimization of their customers’ business processes and competitive positions, Vanderlande focuses on enhancing operational efficiency and expanding its logistical achievements through close cooperation with clients. With an extensive portfolio of integrated solutions, including innovative systems, intelligent software, and life-cycle services, Vanderlande delivers fast, reliable, and efficient automation technology to clients worldwide.

For more information about Vanderlande Industries and their innovative logistics solutions, please visit their website at https://www.vanderlande.com/

Leerkes Engineering has provided invaluable support to Vanderlande’s R&D department, specifically in the areas of Electro/Mechanical typicals and issue analysis. These critical activities were carried out remotely, with frequent contact with Vanderlande employees to ensure seamless collaboration. Additionally, Leerkes Engineering supervised workers from India who were integral to the R&D process at Vanderlande. Furthermore, Leerkes Engineering performed numerous safety calculations and trained other colleagues to work with the safety tool Sistema, thereby facilitating safety calculations for Vanderlande’s machines.

Dromec Winches Ltd. Rhenen

Dromec is a dynamic and innovative company that specializes in the development of winches, winch systems, controls, and software. Their team is enthusiastic and dedicated to designing systems of varying sizes, ranging from small to large and complex systems that meet the highest standards of safety and ease of use. Dromec works closely with certified bodies such as DNVGL, BV, ABS, and Lloyds to ensure that their products meet international regulations.

To learn more about Dromec Winches and their products, please visit their website: https://www.dromecwinches.nl/

Leerkes Engineering has successfully verified a cleanroom portal crane against the NFPA 79 standard. The findings of this verification are documented in an English-language report that also includes recommendations for the portal crane. Additionally, Leerkes Engineering has designed a FAT checklist for NFPA 79 on location.

AMF Bakery Systems Ltd. Bunschoten

AMF Bakery Systems is a proud member of the Markel Food Group family of companies, which includes Reading Bakery Systems and Solbern. Our combined expertise in a wide range of automated food processing solutions, including soft bread and buns, artisan bread and rolls, pizza and flatbreads, pastries and croissants, cakes and pies, snack foods, as well as food product folding and container filling solutions, positions us as global market leaders. Through our partnership, we can leverage each other’s technologies, best practices, and resources to deliver exceptional value to our customers and help feed the world.

For more information about AMF Bakery Systems and our products, please visit our website: https://amfbakery.com/

Leerkes Engineering, in collaboration with a colleague freelancer, has completed the electrical engineering for a bread oven system that complies with the NFPA 79 standard. These activities were carried out remotely with frequent communication with the employees of AMF Bakery Systems.

Reliant Group Ltd.

Reliant Group is a global engineering, service, and commissioning support company that specializes in industrial automation. They offer ad-hoc project support as well as in-house services, including engineering and project realization, to better serve their customers. The company was founded in 2020 by combining the expertise of Dimitri Smoor (Reluctor) and Richard Naber (Prefent) after years of experience in the field of industrial automation. The main objective of Reliant Group is to provide their customers with enhanced support and a broader range of services.

For more information about Reliant Group and their services, please visit their website: https://reliantgroup.nl/

Leerkes Engineering has completed the electrical engineering for a container crane located in the Amsterdam port. Our team replaced outdated components in the control panels with the latest standard. We carried out this work remotely, with frequent communication with Reliant Group’s employees.

In addition, Leerkes Engineering has performed electrical engineering for a Carrot scraper machine, which included thermal, safety, and load balance calculations. We also carried out electrical engineering for a kale collard greens centrifuge machine, including the same calculations and using the 3D tool Eplan Pro Panel to design the panel layout.

Cekamon Saws Ltd.

Cekamon Saws specializes in the development of machines and installations that allow pallet companies to efficiently sort, dismantle, repair, and produce pallets, while addressing specific challenges faced by their customers. They provide tailor-made solutions to pallet processing and constantly strive to improve themselves, incorporating the latest and proven techniques to benefit their clients.

To learn more about Cekamon Saws and their innovative solutions, please visit their website at https://www.cekamonsaws.com/

Leerkes Engineering has collaborated with Cekamon Saws to develop and implement a new Eplan Electric P8 standard and corporate identity within the company. Our team also updated Autocad drawings of machines to reflect the new style with Eplan Electric P8. These activities were carried out remotely, with frequent communication with Cekamon Saws’ employees.

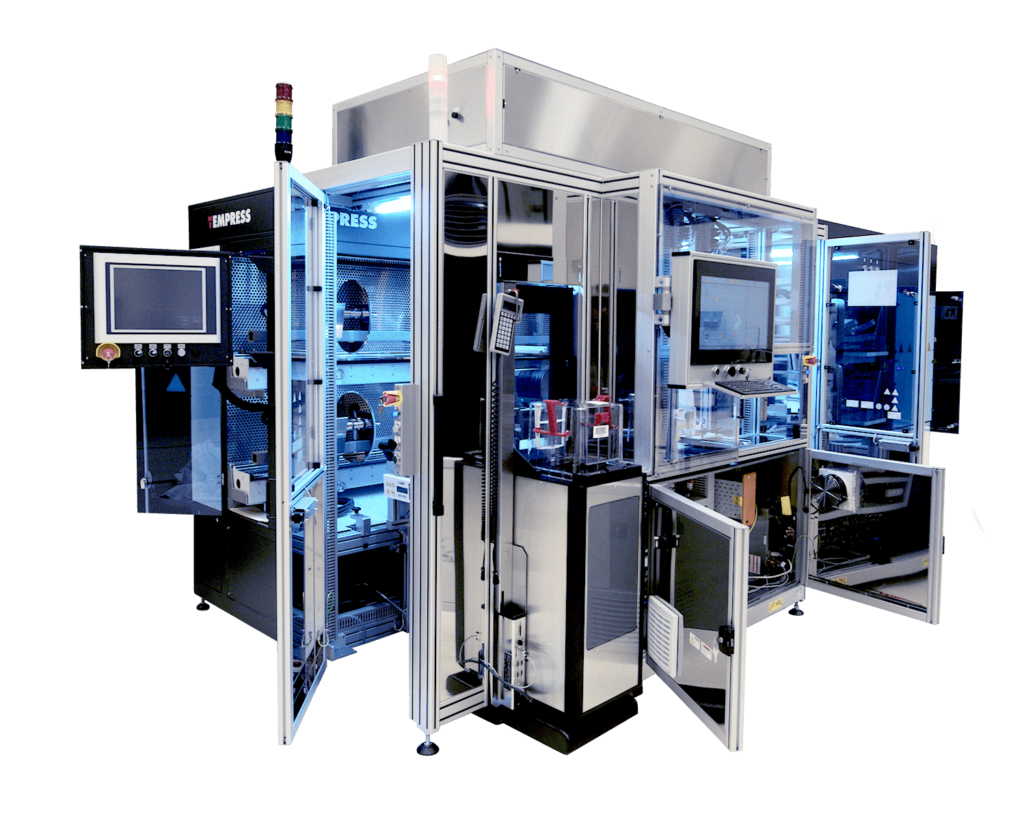

Tempress Systems Ltd.

Tempress Systems is a leading provider of advanced furnace solutions for customers in a variety of markets, including semiconductors, power, MEMS, photonics, solar, life sciences, and coatings. With over 50 years of experience in developing and producing diffusion and deposition equipment and related processes, Tempress is known for its flexibility, innovation, quality, and dedication to meeting the needs of its customers.

In the field of wafer manufacturing applications, Tempress offers a range of processes designed to enhance wafer quality and value, including annealing, wet/dry oxidation, and LPCVD polysilicon. These process solutions enable the production of SOI (Silicon-on-Insulator) and POI (Piezo-on-Insulator) wafers, which are critical for many innovative device architectures and future technological advances.

For more information about Tempress Systems and its innovative furnace solutions, please visit the company’s website at https://www.tempress.nl/

Leerkes Engineering has provided valuable support to Tempress Systems by verifying a high-tech wafer furnace against the NFPA 70/79 standard, and incorporating findings and recommendations directly into the project. Additionally, Leerkes Engineering has taken on the role of Lead Engineer, providing guidance and support to newly hired and junior engineers, and developing a standardization project to help Tempress finish projects faster and more efficiently.